What are the advantages of the automotive high-voltage relay helium inspection equipment produced by HCTE?

Dec 11, 2024

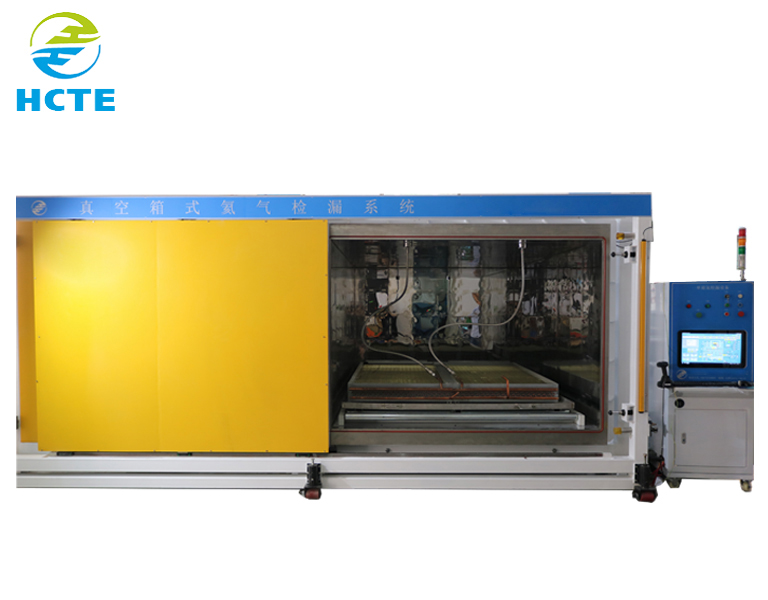

In the field of automobile manufacturing, the quality and performance of automotive high-voltage relays are crucial. As a key inspection tool to ensure their sealing, the helium inspection equipment produced by HCTE provides a strong guarantee for the production and quality control of automotive high-voltage relays with many outstanding advantages.

High-precision inspection capability:

HCTE's helium inspection equipment uses advanced technology and precision sensors to detect extremely small helium leaks with extremely high detection accuracy, which can reach or even exceed the industry-leading level. For automotive high-voltage relays, which have extremely high requirements for sealing, this advantage can effectively detect potential tiny leaks and ensure the reliability and safety of products under complex working conditions such as high voltage and high current, thereby avoiding relay failures caused by leakage problems and possible problems with the automotive electrical system.

Efficient inspection speed:

In the fast-paced environment of automobile production, efficiency is competitiveness. HCTE's helium inspection equipment has the ability to quickly detect and can complete the inspection task of automotive high-voltage relays in a short time, greatly improving production efficiency and reducing waiting time and cost consumption in the production process. This enables automakers to produce more high-quality relays within a limited time, better meet market demand, and enhance the economic benefits and market competitiveness of enterprises.

Wide compatibility and adaptability:

Automotive high-voltage relays come in a variety of types, specifications and sizes. HCTE's helium inspection equipment fully takes this into account and has strong compatibility and adaptability. Through simple parameter adjustment and tooling replacement, the equipment can easily cope with the inspection needs of different types of relays, without the need to configure inspection equipment separately for each relay, saving a lot of equipment procurement costs and equipment floor space for enterprises, and improving the utilization rate of production resources.

Highly intelligent and automated:

The equipment is equipped with an advanced intelligent control system and a user-friendly automated operation interface, realizing a fully automated process from relay loading, inspection to data recording and result judgment. Operators only need to perform simple settings and monitoring to complete the entire inspection process, which not only reduces labor intensity, but also reduces the impact of human factors on the inspection results, and improves the consistency and accuracy of the inspection results. In addition, the equipment also has the functions of automatic data storage, query and analysis, which facilitates enterprises to trace and manage production data and provide strong support for quality improvement.

Stable and reliable performance:

The equipment on the automobile production line needs to run stably for a long time, and HCTE's helium inspection equipment performs well in this regard. It uses high-quality components and advanced manufacturing processes to ensure that the equipment has stable and reliable performance during long-term continuous operation and is not prone to failure. Even in harsh production environments, such as high temperature and high humidity, the equipment can still maintain a good working condition, providing stable and reliable detection guarantees for the quality control of automotive high-voltage relays, and reducing production delays and quality risks caused by equipment failures.

Easy to operate:

HCTE is well aware of the importance of user experience, so it fully considers the ease of operation in the design of the equipment. The operating interface of its helium inspection equipment is simple and intuitive, easy to understand and operate, and can be used without complex training by professional technicians. For automobile manufacturers, this can quickly put the equipment into production, reduce personnel training costs and time costs, and improve production efficiency.

Powerful fault diagnosis function:

In order to help companies solve problems encountered in the production process in a timely manner, HCTE's helium inspection equipment also has a powerful fault diagnosis function. When the equipment detects an abnormal situation or a leakage problem in the relay, it can accurately locate the fault point and provide detailed fault information and solutions to help maintenance personnel quickly repair the problem, reduce equipment downtime, and improve production continuity and stability.

Safety and environmental protection characteristics:

While focusing on production efficiency and product quality, HCTE also attaches great importance to the safety and environmental protection performance of the equipment. Helium, as a detection medium, has the characteristics of non-toxic, odorless, and non-flammable, and is relatively safe for operators and the environment during use. In addition, the equipment is designed with a sealed structure and safety protection device to effectively prevent helium leakage from polluting the environment, while also ensuring the health of the operator, which meets the requirements of modern automobile manufacturers for safe production and environmental protection.

The automotive high-voltage relay helium detection equipment produced by HCTE plays an important role in the production and detection of automotive high-voltage relays with its many advantages such as high precision, high efficiency, high compatibility, high degree of intelligent automation, stable and reliable performance, simple operation, strong fault diagnosis ability, and safety and environmental protection. It provides high-quality and reliable detection solutions for automobile manufacturers and helps the high-quality development of the automotive industry.